Carbon Bike Check - certified according to EN4179 aerospace standard

Non-destructive testing of carbon frames

The non-destructive testing is carried out by www.carbon-bike-check.com in Dinslaken. Contact person is Mr. Carl. Contact details see below.

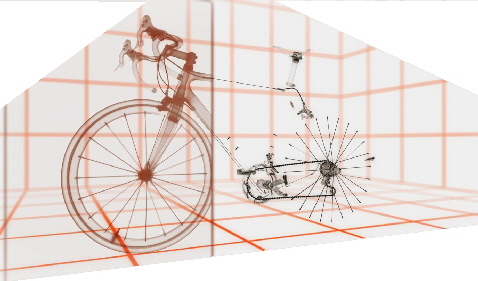

Active thermography has been successfully used since 2000 in the aerospace industry for non-destructive and imaging testing of anisotropic lightweight structures and metallic engine parts. The principle of the test method is based on the measurement of an artificially generated heat flow into the component, which is disturbed in the area of defects and shows thermal reactions on the sample surface.

The essential part of the test is the ultrasonic excitation

With this excitation, ultrasound is introduced into the frame to generate high-frequency vibrations. In the area of a damage, e.g. due to a crack or an adjacent delamination, heat is generated due to the damping in this area, which is detected by the high-resolution camera. Defects that cannot be detected with pulse excitation can be detected with this method and the reverse. An error interpretation is very well possible by combining both methods.

Quality must be produced, it cannot be tested

Werner Niefer, German top manager 1989-93 Chairman of the Board Mercedes Benz AG, (*1928 in Plochingen ; † 1993 in Stuttgart)

... but knowing where a flaw is gives you clarity and a basis for further decisions.

jostec - Carbon Bike Service

The problem with carbon, a possible damage is invisible to the eye !

The question of the detectable limit

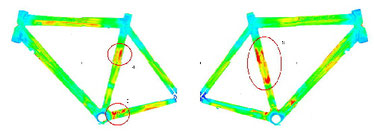

It does not make sense to find the smallest mistake, because the effort would be immense and would probably not be payable. Rather, it is important not to overlook the biggest critical error. An error-free frame looks as follows, the colour ramp used for the evaluation images runs from blue = approx.2 mm via green = approx. 1 mm to red = 0.4 mm.

If a frame becomes very thin in places and the transition between thick and thin is sudden, there is a risk of frame breakage. The risk also depends on how heavy the rider is and how much stress the bicycle is subjected to.

Due to a fall, however, the frame is damaged on one side. Delaminations have been detected at the marked points, which may eventually lead to breakage. Visually this damage is not noticeable. Due to the accident, the fibre fabric may be damaged, which may cause the layers to lift off (delamination). The damage can become larger in the further course and depending on the load and eventually lead to breakage.

The frame was bought at an auction on Ebay and clearly shows a hidden (and concealed) accident damage.

Guide prices and contact for framework tests

carbon fork 90,- € gross

carbon frame 180,- € gross

carbon frame set 240,- € gross

For an offer please send us an e-mail to :

E-Mail bikechecker@carbon-bike-check.com

Dipl.-Ing. Volker Carl

Ingenieurbüro für Messtechnik und Prüfsysteme

Thyssenstrasse 183a

46535 Dinslaken, NRW

Source and further information at www.carbon-bike-check.com

Share with friends

Start your request help(at)carbon-bike-service.eu via e-mail or via online form on our CONTACT page.