Guest contributions from other companies in carbon production, development and materials testing

non-destructive testing of carbon bikes

Comparison of IRT (InfraRedThermography) and CT / X-ray

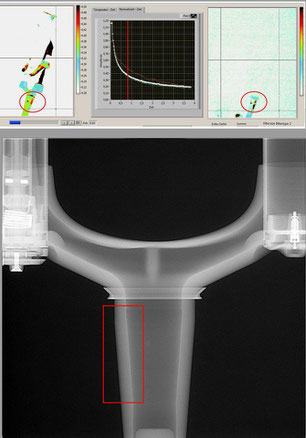

Interesting comparison of impulse thermography or sonotherm and CT / X-ray. After a proper delamination was detected in the shaft of this fork, the customer was advised to replace it. The customer sent the fork to a well-known manufacturer, who then performed a "CT". The CT showed no abnormality and the customer was wished a lot of fun with his fork in the coming summer. To this I say: hopefully the customer will survive the coming summer.

Hidden damage on a carbon fork stem

Here is a prime example of how non-destructive material testing provides an indication of delamination in the fork steerer and is confirmed after exposure.

The Carbon Bike Check, company Carl Messtechnik, did the evaluation and based on the diagnostic images we were able to locate and reveal the correct place. First of all, a longitudinal crack was uncovered, discovered, and in the deeper layers an additional local transverse crack was then formed, with a cavity, indicating a clear manufacturing defect.

We have now sanded out the area, see pictures, and closed it with fresh laminate again, so that the fork can continue to be used without hesitation.